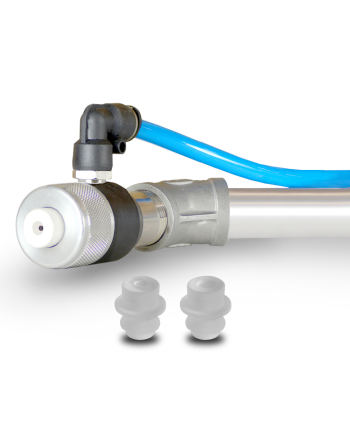

PLASTER AND PLASTER FINISH GUNS

(6)PLASTER GUN – APPLICATION

Plaster guns are pneumatically powered and can be used to spray:

- Facade plasters: silicone, silicate, SiSi, acrylic, and mineral.

- Cement-lime and gypsum plaster

- Wall spackling

- Structural, slurry, and hydroinsulation paints

- Plasters, also gypsum plaster finish

- Liquid wallpaper

- Grafting primer

- Glue onto mesh

We offer Agrekom plaster guns where the material is supplied from below, without the inconvenient hopper at the top. we have Agrekom plaster gun (material supplied from below - no inconvenient hopper at the top of the gun) Such a solution makes it easier to transport the material to the spray gun and prevents unnecessary lifting.

PLASTER GUN – PROFESSIONAL OR SEMI-PROFESSIONAL?

When choosing a plaster gun, you should think about what it will be used for.

We offer spray guns for professional and semi-professional use. Thanks to that, it is possible to match the equipment to the intensity of the work that we are doing.

Professional spray guns are characterised by high efficiency and wide spray stream of material. They are designed for high intensity work done on large areas.

Spray guns for semi-professional use are designed for work of slightly lower intensity.

GUN FOR SPRAYING GYPSUM PLASTER FINISH

In our offer of plaster guns, there are also devices designed for spraying finish. A plaster mass applied with a flat stream makes it possible to precisely cover hard-to-get places with finish. A wide fan of the stream guarantees even covering of the surface. Spraying finish with a gun helps save time, also when grinding the surface. An even layer of finish makes it easier to achieve a perfectly smooth surface when grinding.